Shot Blasting

Shot Blasting

Shot blasting is a surface preparation process that involves propelling small steel shots at high velocity onto a surface. This method is commonly used to clean, strengthen, or polish metal surfaces by removing rust, scale, and other contaminants.

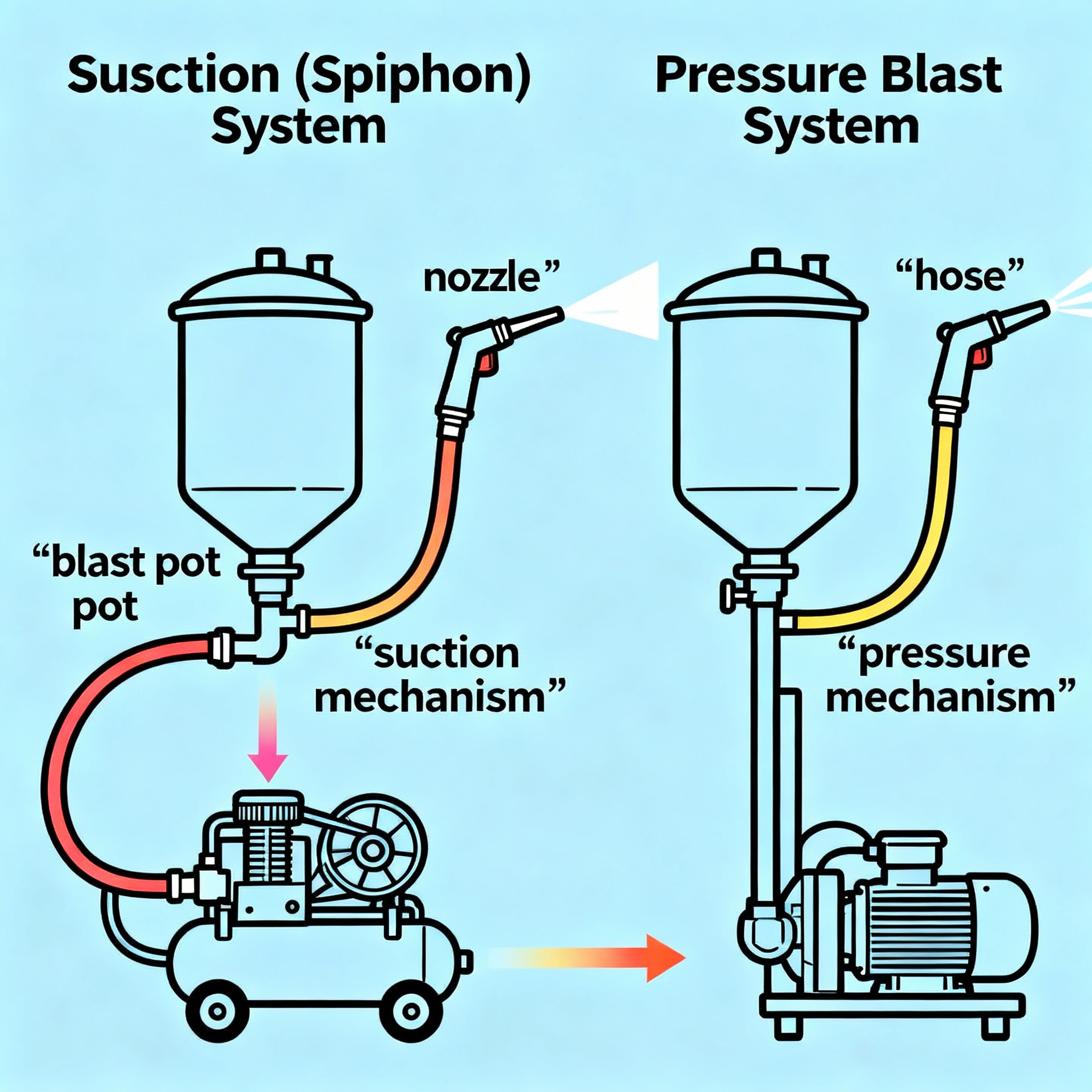

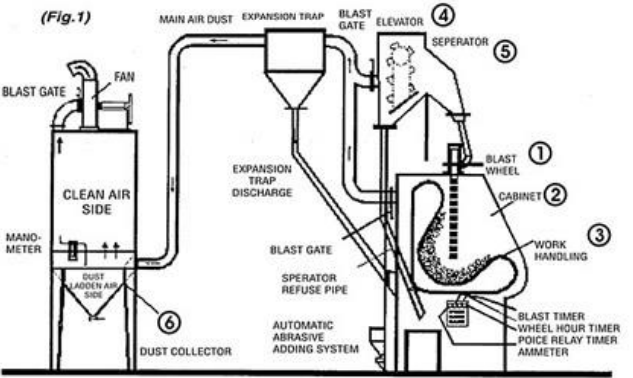

The process can be performed using various types of shot blasting machines, including wheel-type machines, air-blast machines, and tumble blast machines, depending on the size and shape of the workpiece and the desired finish.

Benefits of Shot Blasting

Shot blasting effectively removes surface contaminants and prepares metal surfaces for coating or painting. It enhances surface durability by inducing compressive stresses, increases fatigue resistance, and improves adhesion for subsequent treatments. Shot blasting is faster and more environmentally friendly compared to other abrasive methods.

Our Benefits

We provide professional shot blasting services using advanced equipment designed for precision and efficiency. Our skilled team ensures thorough surface preparation tailored to your project requirements, prioritizing safety and quality results.