Sandblasting

Sandblasting

Sandblasting is the process of smoothing and cleaning a hard surface by forcing solid particles across that surface at high speeds using compressed air. This technique is widely used to prepare surfaces for painting, remove rust, and clean metal, glass, and concrete surfaces.

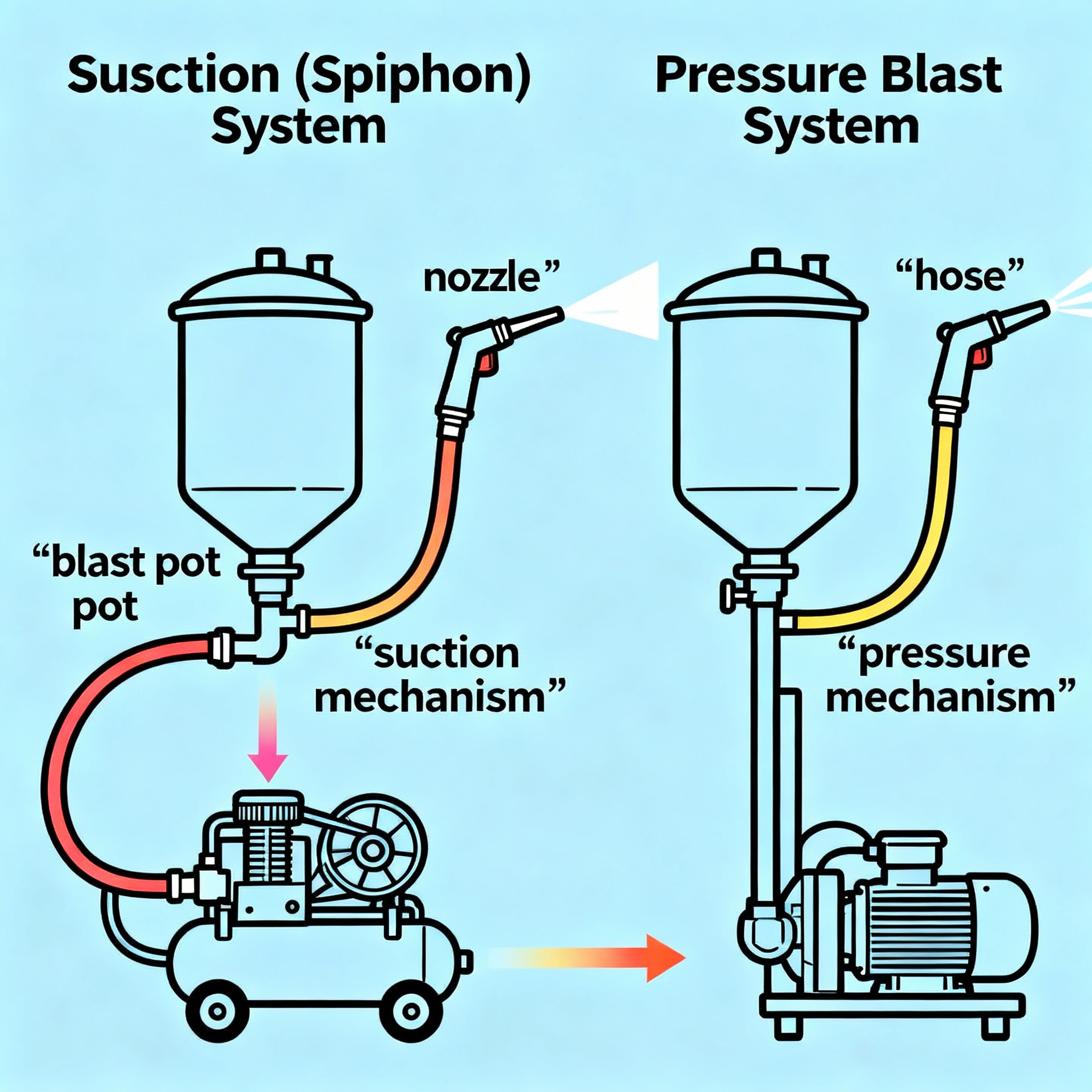

There are two main types of sandblasters: “Suction” (or “Siphon”) and “Pressure” Blast Systems. Suction systems draw the abrasive material through the nozzle by suction, making them suitable for lighter jobs and portable use. Pressure blast systems push the abrasive at high pressure, allowing for more aggressive cleaning and faster results, often used in industrial applications.

Benefits of Sandblasting

Sandblasting effectively removes paint, rust, and other surface contaminants, leaving a clean, smooth surface ready for finishing. It can improve the adhesion of paints and coatings, extend the life of materials, and restore surfaces to a near-new condition.

Our Benefits

We provide professional sandblasting services using state-of-the-art equipment to ensure precision and efficiency. Our experienced team is committed to quality and safety, delivering excellent results tailored to your needs.